Storing Hard Cheeses in Parchment Paper: Optimal Freshness

Controlling Moisture: A Foundation for Success

Maintaining optimal moisture levels plays a pivotal role across countless industries, from food preservation to construction material durability. Mastering moisture dynamics empowers us to reduce hazards while enhancing outcomes. Effective moisture management isn't just about avoiding harm—it's about unlocking peak performance. This complex endeavor requires recognizing the multiple elements affecting water content and deploying targeted solutions to regulate them.

Water presence takes many forms with sector-specific consequences. Consider how building humidity fosters mold and weakens structures, while arid soil stunts agricultural yields. Grasping these varied effects forms the bedrock of successful intervention planning.

Understanding Moisture Sources

Pinpointing moisture origins initiates proper regulation. Subsurface water, ambient humidity, and internal condensation all potentially elevate moisture content. Accurate source identification enables precise preventive actions.

Environmental-specific moisture contributors demand customized responses. A compromised roof demands different remedies than stagnant air in an enclosed space. Correct source diagnosis directly informs effective solution selection.

Moisture Measurement and Monitoring

Precise quantification and ongoing tracking form the backbone of competent moisture management. Specialized instruments provide objective assessments across environments, facilitating data-informed decision-making about necessary adjustments.

Continuous observation reveals moisture patterns that often expose root causes like seepage or airflow deficiencies. Early problem detection dramatically reduces potential harm and prevents chronic complications.

Implementing Control Strategies

Appropriate moisture regulation tactics are vital for damage prevention and condition optimization. Solutions range from vapor barriers to enhanced air circulation systems and humidity reduction equipment.

Strategy customization must account for environmental conditions, material characteristics, and desired results. Successful deployment hinges on meticulous preparation and precise execution. Neglecting these aspects may yield ineffective or detrimental outcomes.

Prevention and Mitigation Techniques

Proactive moisture controls typically outperform reactive measures. Preventative actions like sealing penetrations, upgrading insulation, and utilizing water-resistant materials significantly reduce moisture risks.

For existing moisture challenges, robust remediation including dehumidification systems or water diversion methods proves essential. The most durable solutions integrate preventive safeguards with powerful corrective actions.

Maintenance and Evaluation

Consistent upkeep of moisture management systems ensures sustained performance. Routine examinations and timely repairs prevent failures while maintaining operational excellence.

Continuous assessment of implemented strategies identifies improvement opportunities. This involves analyzing moisture data, evaluating system effectiveness, and making necessary refinements. Periodic review guarantees that moisture solutions remain optimally functional through changing conditions.

Optimizing Storage Conditions Beyond Parchment

Optimizing Cold Storage for Perishables

Refrigeration optimization is paramount for preserving perishable product integrity. Temperature consistency stands as the cornerstone of preservation, as variations accelerate degradation. Humidity balance proves equally critical—excessive dryness causes dehydration while surplus moisture encourages microbial proliferation. Continuous parameter monitoring and adjustment prevents waste while extending shelf life.

Temperature Control Strategies

Precision climate systems are indispensable for ideal storage conditions. Constant supervision and calibration maintain optimal thermal ranges. Advanced monitoring technology enables instantaneous tracking, allowing preemptive responses to potential deviations. This forward-thinking methodology minimizes product decline while ensuring uniform quality throughout storage duration.

Humidity Management Techniques

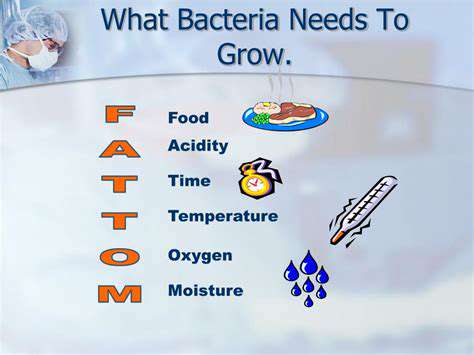

Moisture level regulation remains equally vital for perishable protection. Elevated humidity creates microbial breeding grounds, while insufficient moisture promotes desiccation and structural compromise. Climate control devices like humidifiers and dehumidifiers preserve ideal atmospheric conditions. This meticulous moisture control is fundamental for preventing decomposition and maintaining product wholesomeness.

Proper Packaging and Material Selection

Storage containment choices profoundly influence preservation outcomes. Appropriate materials that regulate moisture exchange are indispensable. Product-specific material selection makes the critical difference. Superior packaging not only shields contents from environmental factors but actively contributes to quality maintenance. Considerations must include permeability, moisture resistance, and thermal stability characteristics.

Storage Location and Layout Optimization

Strategic product placement within refrigeration facilities ensures effective preservation. Air current mapping throughout storage areas ensures uniform cooling distribution. Intelligent spatial arrangement prevents thermal inconsistencies that compromise product quality. Efficient organization also streamlines inventory management and retrieval processes.

Employee Training and Compliance

Comprehensive staff instruction in preservation protocols guarantees consistent standards. Protocol mastery ensures refrigeration operation excellence. Training must cover temperature monitoring, humidity regulation, and proper perishable handling. Ongoing education maintains regulatory compliance and operational best practices.

Regular Inspection and Maintenance

Systematic facility and equipment checks preserve optimal storage environments. Immediate issue resolution prevents product compromise. Examinations should identify leaks, equipment failures, or other environmental threats. Preventive maintenance prolongs equipment lifespan while ensuring uninterrupted functionality.

- Authentic Irish Stew: Hearty and Comforting

- How to Store Avocados: Ripening and Storing

- How to Choose the Freshest Seafood at Your Market

- Low Carb Breakfast Ideas: Keto Friendly and Satisfying

- Grilling Basics: Perfect Burgers Every Time

- Understanding Food Labels: What to Look For and Avoid

- Cooking for Special Diets: Allergies and Intolerances

- Authentic Portuguese Custard Tarts: Pastel de Nata

- Plant Based Diet for Beginners: Easy Transition Tips

- Unveiling Japanese Street Food: Takoyaki and Okonomiyaki

- Authentic Italian Risotto: Creamy and Flavorful

- Authentic Mexican Street Tacos: Carnitas Recipe